Ultrasonic welding is an advanced technology that utilizes high-frequency sound waves to join materials,

often plastics, by creating localized heat through molecular vibrations. At the heart of this process is the

ultrasonic horn, which plays a crucial role in transmitting the ultrasonic energy needed to melt and bond

materials.

However, the ultrasonic horn must withstand significant stress, including both compression and

tension, during its operation. This is why selecting the right material for manufacturing ultrasonic horns

is essential to ensure performance, durability, and efficiency during the plastic welding process.

The ultrasonic horn acts like a spring, stretching and shrinking in length during the welding process due to

the rapid vibrations it undergoes. In a typical 20 kHz ultrasonic welding system, the horn is designed to be

approximately one-half wavelength long, meaning that it vibrates 20,000 times per second. Each vibration

causes the horn’s molecular structure to expand and contract, creating the necessary pressure and friction to

weld the materials together.

As the horn vibrates, it alternates between compression and tension. This constant cycle of expansion and

contraction stresses the horn’s material, making it essential that the selected material possesses both the

mechanical strength to withstand these forces and the acoustical properties to ensure efficient energy transfer.

Selecting the right material for ultrasonic horns involves considering a variety of factors, including the

material’s acoustical properties, mechanical strength, fatigue resistance, surface hardness, cost-effectiveness,

and durability. These factors directly affect the horn’s performance, longevity, and ability to meet specific

application requirements. Below are three commonly used materials for manufacturing ultrasonic horns

and their respective properties.

· Properties: Titanium boasts a high fatigue strength, exceptional acoustical properties, and good

surface hardness. These qualities make it capable of withstanding the intense vibrations during

ultrasonic welding without significant wear or deformation. Titanium’s ability to resist corrosion

further enhances its durability, especially in harsh environments.

· Applications: Titanium is especially suitable for applications that require high amplitude, such as

when working with tougher materials or in applications where a higher power is needed.

Additionally, titanium horns are often used when a hard surface is required to prevent wear and

improve performance.

· Challenges: Despite its many benefits, titanium is an expensive material and not always readily

available in the desired size ranges. This can make it a less viable option for some manufacturers,

particularly those with limited budgets or specific size requirements.

· Coatings: To enhance titanium’s surface properties, it can be coated with materials like Carbide,

Nickel, or Teflon. These coatings improve surface hardness and help protect the horn from wear in

high-amplitude applications.

· Cost-Effectiveness & Durability: Titanium is often seen as a high-performance material, and

while its cost is significant, it offers a long lifespan, high wear resistance, and excellent acoustic

properties. These attributes justify its higher cost in long-term, high-volume applications.

Product Example:

Medical Device Manufacturing (Ultrasonic Welding for Surgical Instruments)

Titanium horns are frequently used in the medical device industry, especially in applications involving

surgical instruments. These tools often require high-frequency ultrasonic welding to join plastic

components, like handle grips to surgical blades, where precision and durability are paramount.

Titanium horns are chosen for their high amplitude and wear resistance, ensuring that the welding

process remains reliable even after extensive use.

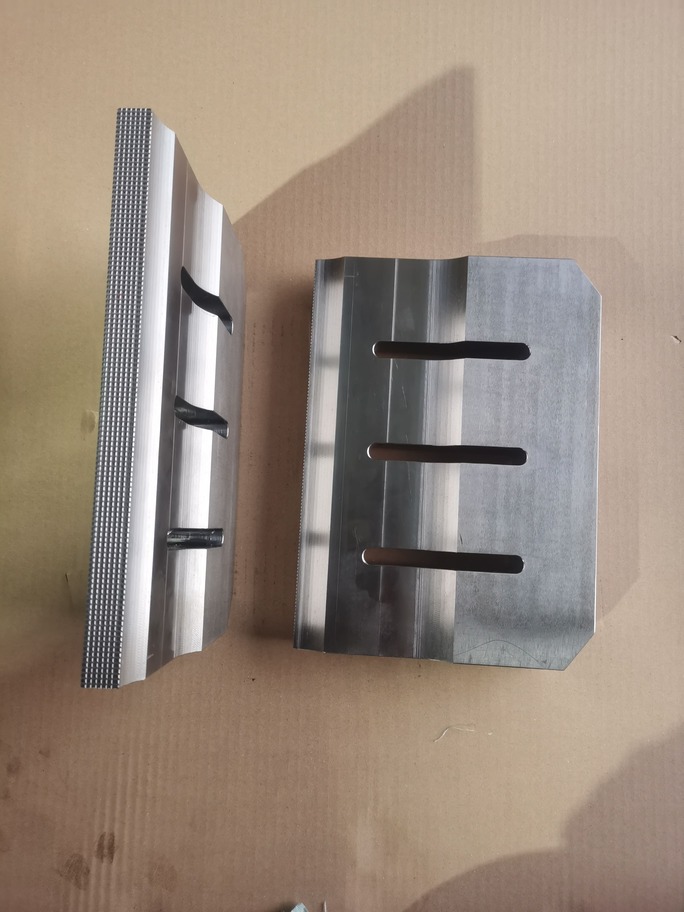

· Properties: Aluminum is lightweight and has excellent acoustic properties, making it highly

effective in transmitting ultrasonic energy. It is widely available in various sizes, making it a

good option for a range of ultrasonic welding applications.

· Applications: Large ultrasonic horns, especially those over 4.0" in diameter or 11.0" in width,

are typically made from aluminum. It is also the material of choice for prototype horns due to

its low cost and availability in large sizes.

· Benefits: Aluminum is easy to machine, reducing both production time and labor costs.

This makes it an attractive option for manufacturers looking to create complex horn designs

quickly and efficiently.

· Challenges: Aluminum’s major drawbacks are its relatively poor surface hardness and moderate

fatigue strength. These properties can limit its suitability for long-term, high-wear applications.

However, this can be mitigated by applying coatings or plating to the aluminum surface.

· Solutions: Aluminum horns can be coated with chrome, nickel, or carbide to improve wear

resistance and increase their longevity in demanding applications.

· Cost-Effectiveness & Durability: Aluminum offers a cost-effective solution compared to titanium

and steel, especially when the application does not require extreme durability. It provides a good

balance of performance and affordability but may not last as long as titanium or steel without

additional coatings.

Product Example:

Consumer Electronics (Ultrasonic Welding of Plastic Components)

In the consumer electronics industry, aluminum ultrasonic horns are frequently used to weld plastic

parts like casings for mobile phones, tablet devices, or even earphones. Aluminum horns are ideal

for these applications due to their lightweight nature and ease of machining, which enables manufacturers

to produce high-quality welds in shorter production cycles. Furthermore, for prototype designs where

low cost is essential, aluminum provides an ideal material.

· Properties: Steel can be heat-treated to create a wear-resistant surface, making it highly

suitable for applications that involve severe wear, such as metal insertion, welding glass-filled

parts, or plunge cutting.

· Applications: Steel is commonly used in applications where durability is key, such as when

the horn is used in welding processes involving highly abrasive or tough materials.

· Challenges: Despite its strength, steel horns are generally more brittle than those made from

titanium or aluminum. As a result, steel is often used in low-amplitude applications where

the stress on the horn is lower, reducing the risk of material failure.

· Cost-Effectiveness & Durability: Steel is typically more cost-effective than titanium and offers

high wear resistance. However, its brittleness means it has a shorter lifespan in high-amplitude

or high-stress applications. It is suitable for lower-cost applications where long-term durability

and performance are not critical.

Product Example:

Automotive Industry (Ultrasonic Welding for Plastic Parts)

Steel ultrasonic horns are commonly used in the automotive industry, particularly in applications

where components with high durability are needed. For example, steel horns are used to weld

glass-filled plastic parts in car interiors or to perform metal insert welding. These applications

demand a strong material that can resist wear from frequent use, but the welding typically occurs

at lower amplitudes, making steel an ideal material.

Choosing the right material for an ultrasonic horn depends on the specific requirements of the application.

The material’s properties, including acoustical characteristics, fatigue strength, surface hardness, wear

resistance, and cost, must be carefully considered in light of the type of welding process, the materials

being welded, and the operating conditions.

· Expert Advice: Because the selection of ultrasonic horn material can significantly impact the

performance and lifespan of the equipment, it’s important to consult with technical experts.

They can help guide the decision-making process by assessing the unique demands of the

application and recommending the best material based on the specific needs.

The selection of materials for ultrasonic horns is a crucial factor in ensuring the efficiency, durability,

and high performance of plastic welding processes. The material chosen impacts not only the welding

quality but also the longevity and reliability of the equipment. Titanium, aluminum, and steel each offer

distinct advantages and limitations based on their mechanical properties and performance characteristics.

· Titanium: Ideal for high-fatigue strength and acoustic performance but at a high cost. Offers

excellent durability, especially for high-amplitude, high-power applications.

· Aluminum: Offers a more cost-effective solution, especially for larger horns and prototypes,

due to its excellent acoustic properties and ease of machining. However, it may require coatings

for more demanding applications.

· Steel: Well-suited for high-stress, high-wear applications, though its brittleness makes it less

suitable for high-amplitude welding.

The material choice should also consider the nature of the materials being welded, the operating conditions,

and the required lifespan of the ultrasonic horn. In applications involving heavy-duty or high-stress welding,

steel or titanium may be more appropriate, while aluminum might be chosen for lighter, less demanding tasks.

Ultimately, selecting the right material is not a decision to be taken lightly, as it directly influences the operational

efficiency, repair needs, and costs over the lifetime of the ultrasonic welding equipment. Consulting with

technical experts who understand the nuances of ultrasonic welding and the specific needs of each application

can provide invaluable guidance in making the best decision. By carefully considering these factors and

choosing the appropriate material, manufacturers can ensure not only optimal performance but also reduced

maintenance costs and improved overall system reliability. This thoughtful approach to material selection

will result in longer-lasting ultrasonic horns, improved welding outcomes, and a more efficient production process.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangmin, Shenzhen,China 518107