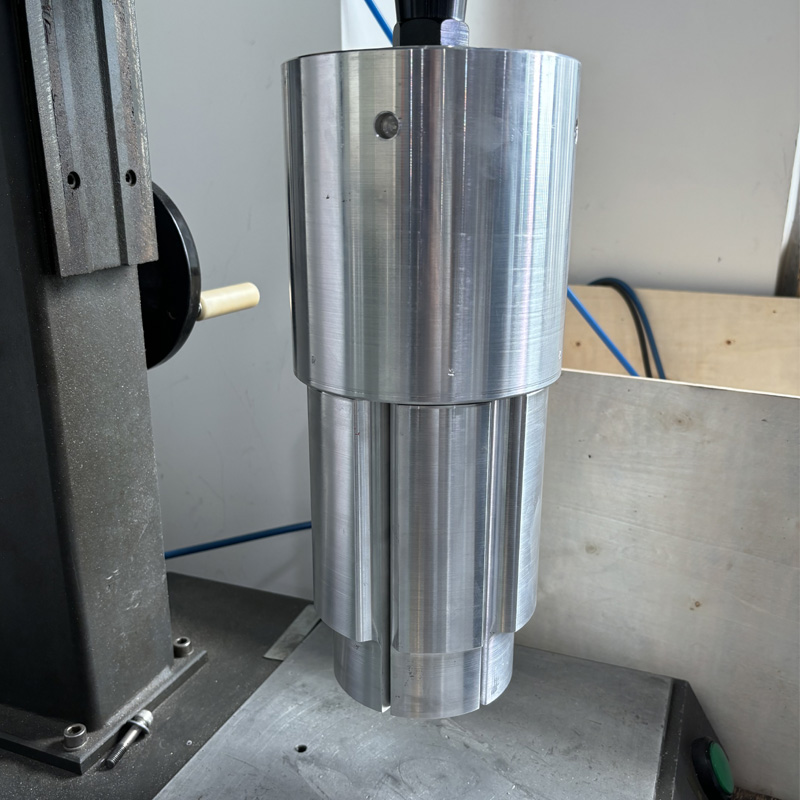

Ultrasonic welding horn also called welding head,which is one of the key for assembling thermoplastic products. Welding horns vary from frequencies(normal 20Khz,15Khz,35Khz,etc.)

Sonotrode, also known as the horn or sonotrode in an ultrasonic welding system, is a critical component that

amplifies and focuses the high-frequency vibrations generated by the transducer to the welding area.

The sonotrode is essentially the business end of the ultrasonic welding system, responsible for transferring

thevibrational energy to the materials being welded.

Sonotrodes are widely used in various fields, particularly in the automotive industry for battery assembly

connections, tab welding, fuse welding, and more.

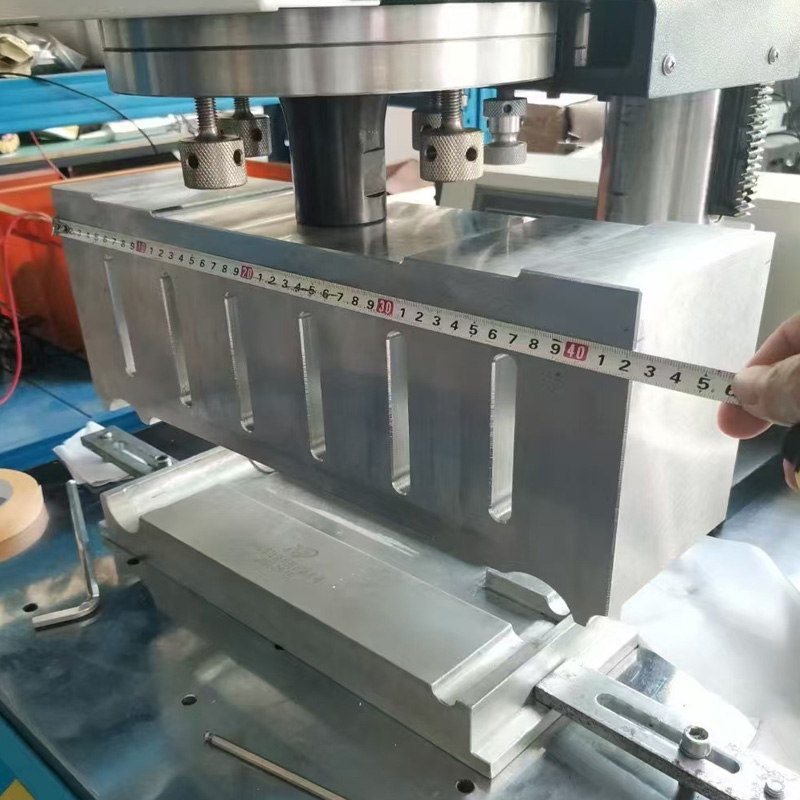

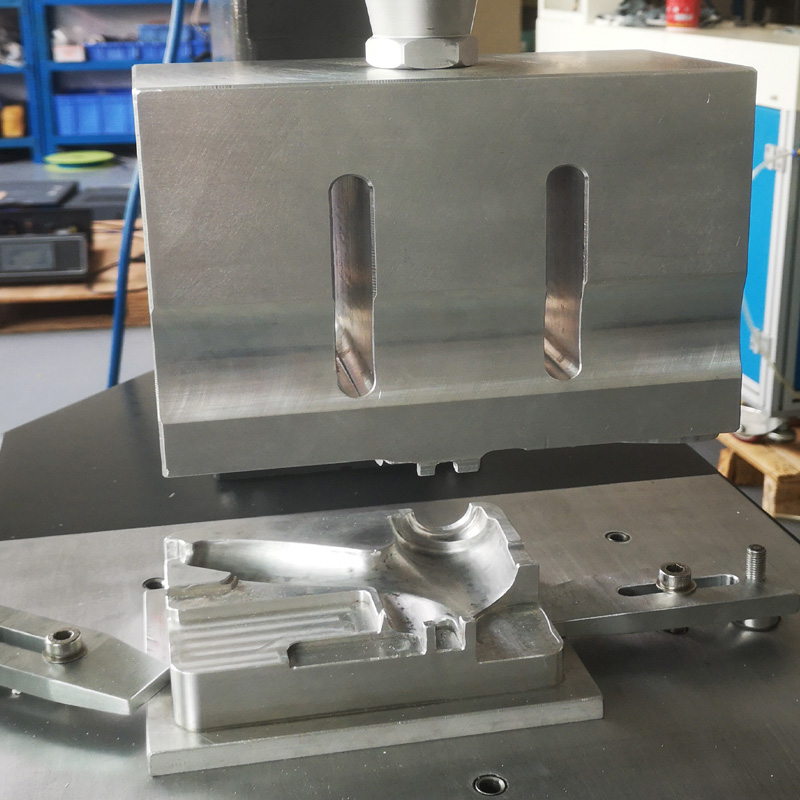

All mold plates are customization to meet different products design and accuracy.

Samples and 3D drawing are required for making horn and bottom mold accordingly.

Horn design is a complex process that requires careful consideration. The right material must

be chosen, the horns need to be balanced, and they must be designed to achieve the desired

amplitude while being precisely tuned to a specific frequency. Poorly tuned horns can potentially

damage the converter or power supply. Tooling Engineers utilize Finite Element Analysis (FEA)

to design and optimize horns, ensuring they are properly tuned, maintain appropriate stress levels,

meet amplitude requirements, and provide uniform performance.

Mechanical Vibration Transfer: The sonotrode amplifies the vibrations produced by the piezoelectric

transducer and evenly distributes them to the welding area. This creates frictional heat at the interface of

the materials, facilitating their fusion.

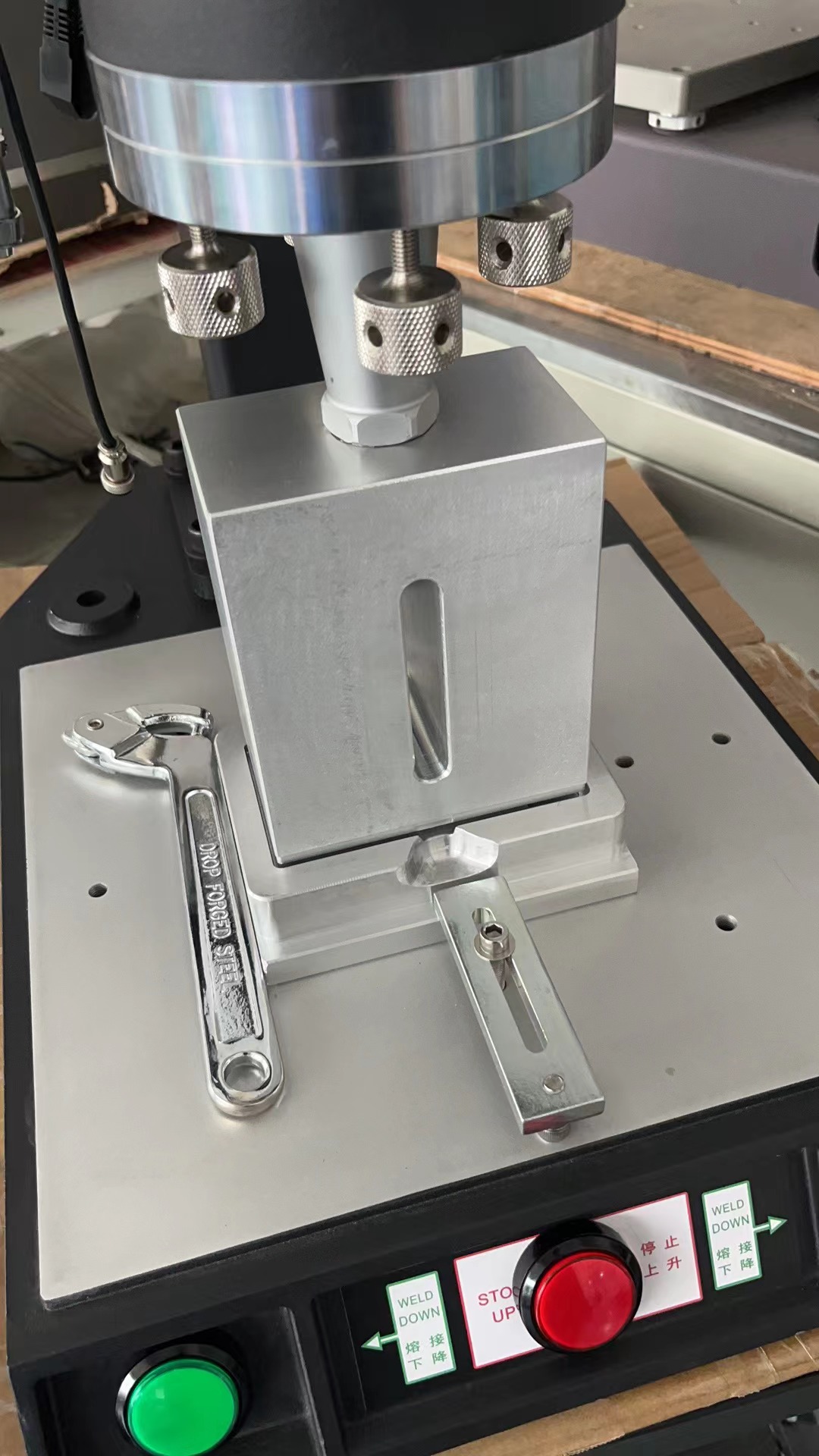

Precision Control:The design and manufacturing of the sonotrode often involve FEM (Finite Element Method)

calculations to ensure optimal oscillatory behavior. Advanced laser measurement techniques are used to

measure and record amplitude distribution, ensuring precision during the welding process.

High Precision: CAD/CAM calculated algorithms ensure precise 3D contour manufacturing for high-precision

welding needs.

Longevity: Special surface treatment processes extend the lifespan of the sonotrode.

Efficiency and Energy Saving: Ultrasonic welding does not require external heating sources, consumes less

electrical energy, and offers fast welding speeds, enhancing production efficiency.

Broad Material Compatibility: Capable of welding various types of materials, including highly conductive,

thermally conductive materials, and difficult-to-weld metals.

High-Quality Weld Joints: The physical and mechanical properties of the weld metal remain unchanged,

providing stronger and more stable joints compared to resistance welding.

Environmentally Friendly: No need for adhesives, fillers, or solvents, making the process environmentally

friendly and free from contamination.

In summary, the sonotrode is a crucial tool in ultrasonic welding systems, playing a vital role across multiple

industries. As technology advances, the performance and application scope of sonotrodes continue to expand.

Contact Us now for a personalized quote and start your journey towards superior product quality and efficiency.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangming, Shenzhen,China 518107

We chat