An ultrasonic welding machine transducer is a critical component of ultrasonic welding equipment, where it plays a key role in converting electrical energy into mechanical vibrations.

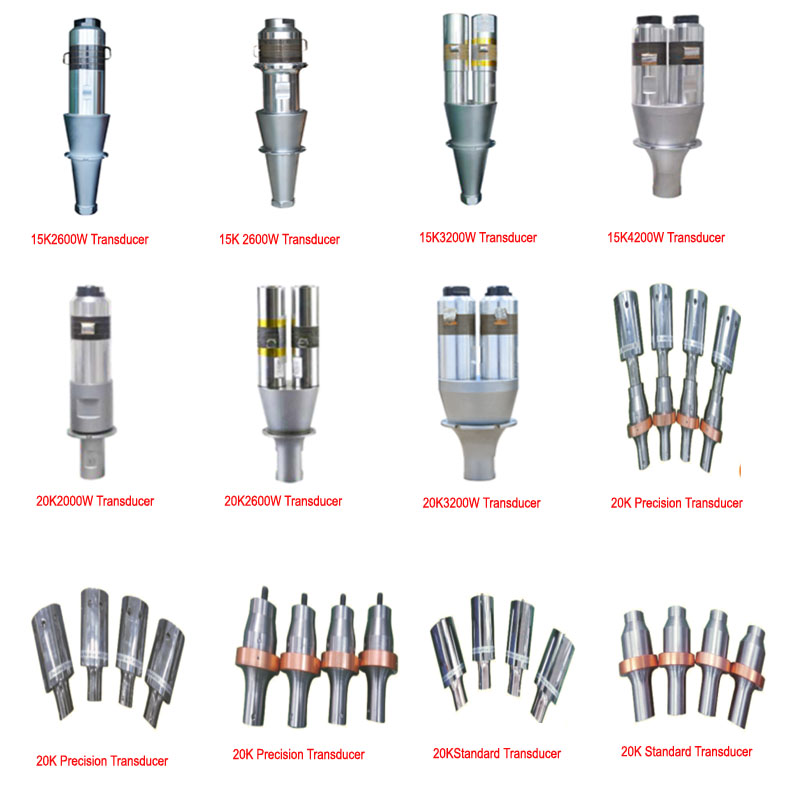

20kHz/ 15kHz Ultrasonic Welding Transducer

The ultrasonic transducer, also commonly referred to as a converter, converts high frequency electrical

vibrations into a mechanical longitudinal vibration with a constant output amplitude.

What all ultrasonic welding converters have in common is their central assembly with solid piezoceramic

four-disk technology. Between each of the disks is a thin metal plate. This forms the electrode, which feeds

the transducer with a sinusoidal electrical signalAs they receive the signal, the discs expand and contract,

which produces resonant mechanical motion. The rigid decoupling principleallows for axial and transverse forces.

When used in conjunction with boosters and sonotrodes, the energy generated is transmitted to thermoplastic

work pieces to weld them together. These piezoelectric devices also can be used on materials that require this unique

type of energy to undergo chemical or physical changes. Special manufacturing processes ensure extremely

long service life at constant output amplitude.

Ultrasonic transducer is a device that converts energy into ultrasonic sound waves (typically above 20 kHz,

which is beyond the range of human hearingzand vice versa. These transducers operate

using the principle of piezoelectricity, where materials produce an electrical charge in response to

mechanical stress or vice versa.The transducer in ultrasonic welding typically operates at frequencies ranging from

15 kHz to 70 kHz, with 20 kHz and 15kHz being the most common in industrial applications.

Key Components:

Piezoelectric Material: The core of the transducer. When an alternating current is applied to it, it vibrates and produces ultrasonic waves.

Backing Material: Reduces the vibrations from the back of the transducer to improve the resolution of the produced ultrasound.

Acoustic Matching Layer: Matches the acoustic impedance of the piezoelectric material with the medium (such as air, water, or tissue)

to minimize reflection and maximize the transmission of sound waves.

Electrodes: Apply electrical signals to the piezoelectric material.

Phone: +86-15989541416

E-mail: michael@sztimeast.com

Whatsapp:+86-15989541416

Add: 3/F, Building 5,Huixin Intelligent Industrial Park, Xinhu, Guangmin, Shenzhen,China 518107